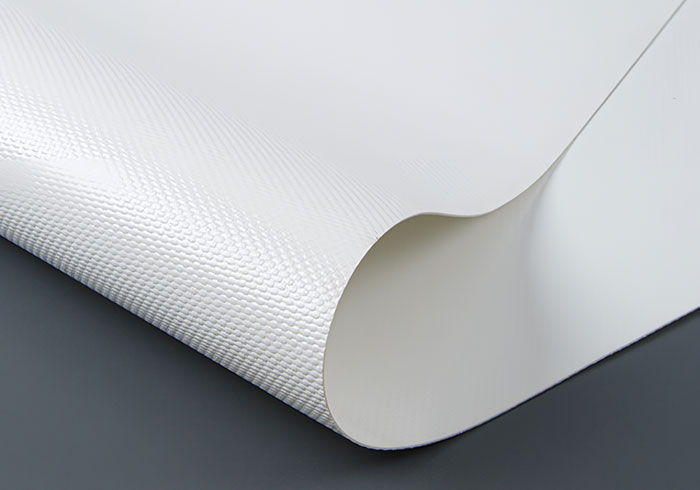

PVC

Polyvinyl chloride (PVC)-coated polyester is the most commonly used material for tensile membrane structures. PVC was chosen for its excellent strength, water resistance, flexibility, transparency and durability. It is the most cost-effective and versatile stretch fabric available in a variety of colors and applications, both permanent and temporary. PVC is treated to be stain, fire and UV resistant.

Available in woven or non-woven materials, PVC has been a staple in the fabric membrane roofing industry since the early 1960s. PVC membranes are a cost-effective alternative to traditional roofing systems and can be produced in a variety of colors to suit the needs of individual building projects. When produced in bright white, this flexible fabric membrane reduces radiant heat gain, keeping indoor temperatures cooler during warm weather conditions.

Technically, PVC is a molecule made up of carbon, hydrogen, and chlorine. The combination of these elements creates a single-layer membrane that is easy to fabricate. During the manufacturing process, remnants can be recycled and melted down for replication, reducing waste.

Because PVC is a thermoplastic, the film can be softened to a semi-solid state and infused with UV inhibitors and anti-fouling biocides. During installation, multiple pieces of fabric can be overlapped and fused together through a process called weldable seam technology. Once cooled at room temperature, the sheets formed a continuous film.

Life

PVC membranes are typically coated with a protective acrylic or PVDF topcoat and have a design life of approximately 15-20 years, depending on the grade of PVC selected, location and exposure to environmental contamination. PVC fabric warranties range from 5 to 15 years, depending on the supplier and application.

Solar energy transmission

PVC fabric reflects approximately 89% of solar energy and allows 9% of visible light to pass through the fabric. Transmission rate depends on fabric color, coating, printing and environment. These coatings may contain antifungal agents. Therefore, the more self-cleaning a fabric is, the less light transmission will be interrupted by dirt adhesion and aging of the fabric.

Application areas

PVC polyester is used in structures around the world and in a variety of environments. Applications include: covered walkways, parking structures, entrance facilities, outdoor classrooms, play areas, sports field fencing, swimming pool fencing and event spaces.

PVC is a strong, foldable fabric ideal for retractable and temporary structures that require frequent disassembly and storage, such as tents, warehouses, restoration and mining structures. PVC can be easily printed on fabric, so it is often used in projects where branding is important.

Sound absorption

PVC can be altered to control the structure’s sound absorption rate. Depending on the requirements of the structure, PVC can be coated with various coatings. For example, an indoor aquatics center will use PVC that has been specially treated to absorb as much sound as possible, while small rooms or areas will benefit from strong soundproofing.

Maintain

PVC-coated polyester is lower maintenance, but it requires more frequent maintenance than self-cleaning PTFE and ETFE. Cleaning frequency depends on the location of the structure, exposure to environmental contaminants, and coatings on the fabric. Varnishes and other coatings can be added to fabrics to significantly extend service life and reduce maintenance requirements.

Sustainable development

PVC is classified as a recyclable fabric, making it an increasingly popular option for green buildings as an alternative to rigid roofing. While there are many processes for recycling PVC, the most common involves melting down the fabric to be replicated. This process does not affect the service life of recycled PVC.

Advantage:

- UV stabilized

- Coating provides long-term protection against staining and premature aging

- Weather tight

- Easy-to-clean surface properties

- As a lightweight (approx. 1,450 g/m2) fire-resistant material with a maximum thickness of approximately 1.2 mm, PVC/PES has an extremely low fire load

- Self-extinguishing

- Various colors

- Printable

- Light transmittance up to 40%

- Life expectancy 20 to 30 years

Main advantages of PVC primary coating:

- Protects fabrics (yarns, fibers) from external influences (moisture, UV radiation, biological and chemical exposure)

- Make fabric weldable

- Make fabric impermeable to rain

Key benefits of PVC topcoat:

- Protects the primary coating from atmospheric effects (moisture, UV radiation, biological and chemical exposure)

- Migration of stabilizers and plasticizers

- Dust-proof treatment makes the membrane surface shiny and not easy to rot