Durability and maintenance strategies of tensile membrane structures

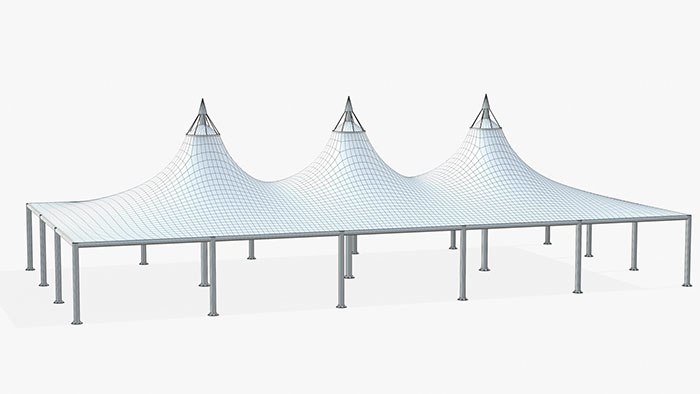

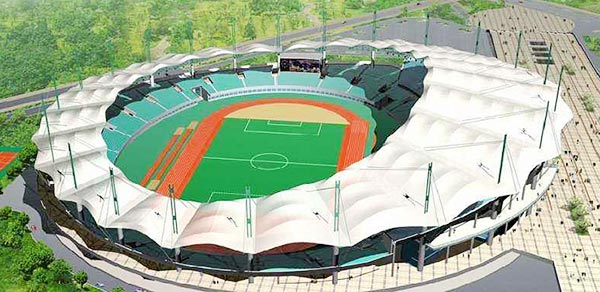

Tensile membrane structures, as a unique architectural form, are widely used in sports facilities, transportation facilities, commercial venues, landscape sketches and other fields due to their lightness, beauty and flexible design. However, the durability and long-term stability of this structure largely rely on scientific monitoring and maintenance strategies. This article will explore the durability of tensile membrane structures and their maintenance strategies in order to provide a useful reference for relevant practitioners.

The durability of tensile membrane structures mainly depends on the selection of their materials and structural design. Generally speaking, the service life of tensile membrane structures ranges from 3 to 30 years, depending on the type and thickness of the membrane material and the environment in which they are used. For example, materials such as polyester fiber PVDF or PVF coated membrane (PVC/PES-IIIII), PTFE/GF-IIII, etc. are often used in durable tensile membrane buildings, with a service life of up to 10-15 years, suitable for small and medium-sized sports facilities, transportation facilities, etc. Polyester PVDF, PVF, Acrylic, PVC coated membrane and other materials are often used in tensile membrane buildings with slightly poor durability, with a service life of 3-10 years, suitable for small sports facilities, commercial activity venues, etc. Temporary tensile membrane buildings mostly use polyester fiber PVF, Acrylic, PVC coating, uncoated fabric membrane, PVC film and other materials, with a service life of less than 3 years, suitable for exhibition venues, entertainment venues, etc.

In terms of maintenance strategy, first of all, it is necessary to regularly check the overall form of the tensile membrane structure to observe whether there is deformation, tearing or damage. Using high-tech means such as drones and laser rangefinders, structural changes can be captured more accurately to ensure that problems are discovered and handled in a timely manner. At the same time, the tension state of the membrane structure is also a key factor affecting its stability and service life. Therefore, special tools such as membrane surface tension meters should be used regularly to measure the tension of the membrane surface to ensure that it meets the design requirements. Once abnormal tension is found, it needs to be adjusted in time to maintain the stability and safety of the membrane structure.

In addition to structural integrity and tension monitoring, cleaning and maintenance of tensile membrane structures are also an indispensable part of maintenance work. Since dust and dirt easily accumulate on the surface of the membrane structure, affecting its beauty and light transmittance, it should be cleaned regularly with a soft cloth or low-pressure water gun. It should be noted that strong detergents or chemicals should be avoided during the cleaning process to avoid damaging the membrane material. At the same time, care should be taken not to damage the membrane material during the cleaning process, and the cleaning personnel must wear soft-soled shoes when walking on the membrane surface.

Waterproof and UV protection treatment is also an important measure to extend the service life of the tensile membrane structure. Regular inspection and application of waterproof coating and UV protection coating can effectively prevent rain erosion and UV aging, thereby extending the service life of the membrane material. In addition, for key components such as steel wires and brackets in the tensile membrane structure, their tightness and wear should also be checked regularly to ensure that there is no looseness, breakage or corrosion. If necessary, they should be replaced and tightened in time to ensure the stability and safety of the entire structure.

In terms of dealing with severe weather, tensile membrane structures also need special attention. Under severe weather conditions such as strong winds and heavy rains, the tensile membrane structure should be closed and locked in advance to avoid wind damage to the structure. At the same time, strengthen inspections to ensure structural safety. When rain and snow continue, water accumulation will damage the membrane material, so the space covered by the membrane surface should be closed to the public, and measures should be taken immediately to avoid new water accumulation.

In summary, the durability and long-term stability of the tensile membrane structure depend on scientific monitoring and maintenance strategies. By regularly checking the structural integrity and tension state, as well as cleaning and maintenance, waterproof and UV protection, and maintenance of steel wires and brackets, it can be ensured that the tensile membrane structure is always in good condition and its service life is extended. At the same time, special measures are also needed to ensure the safety and stability of the structure when dealing with severe weather.