Application of stretch fabric tension structures in sports field

From the dome of the World Cup stadium to the canopy of the Olympic track and field stadium, an innovative material called stretch fabric tension structures are reshaping the global sports industry. It achieves the engineering miracle of “light as a feather and tough as steel” through the combination of high-strength fiber and flexible tension system.

The upgrading of the global sports industry has spawned the demand for stretch fabric tension structures

1. Market size and growth logic

According to Allied Market Research data, the global sports stadium tensile structure market size will reach US$4.78 billion in 2023, of which elastic fabric tension structure accounts for more than 60%, and is expected to exceed US$8.9 billion in 2030, with a compound annual growth rate (CAGR) of 8.3%. The core growth drivers include:

- Large-scale event economy: the 2032 Brisbane Olympics, the 2026 World Cup in the United States, Canada and Mexico, etc. have spawned a new wave of venue construction.

- Sports science revolution: lightweight and highly responsive tension materials are used in the research and development of sports equipment

- Sustainable transformation: Environmentally friendly materials such as recyclable polyester fiber and ETFE membrane replace traditional concrete and steel.

2. Regional market hotspots

North America: Professional sports leagues (NBA, NFL) lead the transformation of smart venues, and the demand for tensile fabric structure roofs has surged.

Europe: Football stadiums and track and field halls use ETFE air pillow structures to achieve natural lighting and temperature control.

Asia-Pacific: China’s “14th Five-Year Plan” sports plan promotes the construction of more than 50,000 sports centers, and India has added 20+ cricket stadiums.

Application scenarios of stretch fabric tension structures in the sports field

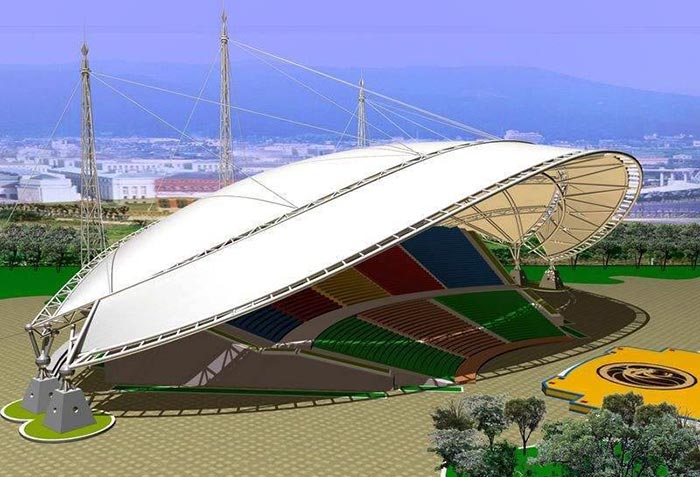

Domes and roofs of sports stadiums

Use PTFE-coated glass fiber or PVC membrane materials to form a large-span column-free space through a two-way tensioning system. For example:

- Qatar World Cup 974 Stadium: Removable tensile structure roof, reducing steel consumption by 30%.

- London Wembley Stadium: ETFE air pillow modules adjust light transmittance and reduce energy consumption by 40%.

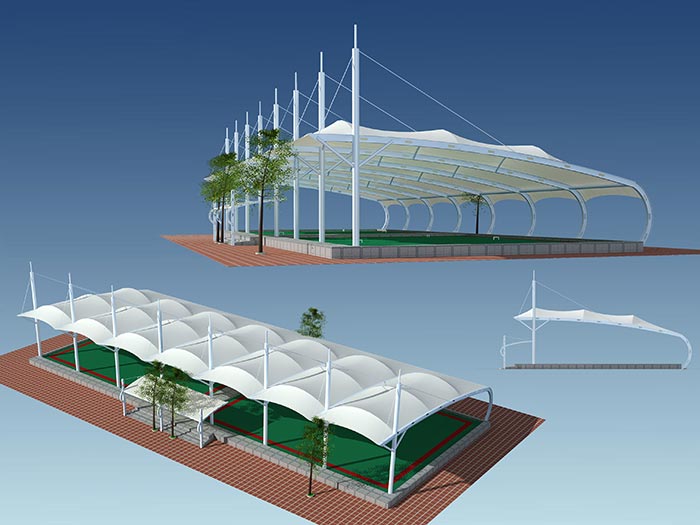

Stands and awnings

Stretch fabric tension structures can quickly build temporary stand roofs to meet the flexible needs of events, with a wind resistance level of 12.

Four core competitive advantages of stretch fabric tension structures

1. Lightweight and high strength

The unit weight strength is 5 times higher than that of steel, and the deadweight of the membrane structure is only 1-2 kg/m², reducing the construction foundation cost by 50%. The elongation at break of the material is less than 3%, ensuring the structural stability in extreme weather.

2. Dynamic response and self-adaptation

The intelligent tensioning system adjusts the fabric prestress in real time through hydraulic rods or shape memory alloys to cope with changes in snow load and wind pressure.

3. Environmental protection and sustainability

The proportion of recyclable polyester fiber has increased to 75%, and the life of ETFE membrane has reached more than 25 years. Membrane structure venues reduce the use of concrete and reduce carbon emissions by 60% compared with traditional buildings.

4. Design freedom

Supports complex shapes such as hyperbolic surfaces and catenaries to create iconic sports landmarks. Digital tensioning simulation (such as ANSYS) optimizes node stress and reduces material waste.

Future trends and challenges in the global market

1. Growth opportunities

Smart material integration: Piezoelectric fiber power generation membranes power the stadium LED lighting, and self-sufficient energy accounts for 15%.

Emerging market explosion: Saudi Arabia’s 2030 vision plans more than 50 smart sports stadiums, and the demand for e-sports stadiums in Southeast Asia has surged.

2. Industry challenges

Cost and technical barriers: High-end PTFE membrane materials rely on imports, and Chinese manufacturers are accelerating domestic substitution.

Lack of standard system: Countries have not yet unified the wind and fire resistance certification of tensile structures, increasing the cost of cross-border projects.

Conclusion

Stretch fabric tension structures are setting off a flexible revolution in the sports industry. In the next 10 years, the global sports tensile fabric structure market will maintain a high growth rate of more than 9%. Whether it is a venue operator or an event organizer, only by seizing this technological high ground can they gain an advantage in the trillion-level sports economic wave.